Iwm Failing With Miniatures

#1

Posted 30 May 2013 - 05:18 PM

http://www.sarna.net...maker-part-two/

As you can see ... a massive difference in quality, and - AND! MW:O Mech designs. Now I dont expect the makers of MW:O to want to hop on the band wagon immidiately but I think that most will admit that the MW:O Mech designs far surpass some of the older Battletech designs. For instance the Jenner and the Stalker ... Yeah was never a major fan of the phallic design behind the original Stalker, but in MW:O it is one of my favorites. I think that if they were to get a company other than IWM to make the MW:O mech designs into playable Battletech Minis they would possibly make a small mint in cash. I can tell you right now i would be a Founder for that program as well!

#2

Posted 30 May 2013 - 06:25 PM

The problem with IWM is that they're so small and operate on such a tight margin that they're almost pigeonholed into their business model. It's a few guys in a hot, small shop pouring metal into rubber molds all day long, with one person working the desk and everybody sorting, packing, and shipping (and remember, BattleTech is not their only product line!). If one staff member is incapacitated, the entire business suffers (recently, one of them broke her leg, which kept her out of the office, and ship times slowed considerably while she recovered). There is no space, revenue, or sales volume to justify and finance the upgrade to plastic injection, much less the molds for that process (which can run into the tens of thousands of dollars...for one.

One of the things about IWM that can be good or bad is that everything is sculpted and cast by hand. Good because real people with sculpting and casting skills are employed doing what they love; the bad being that their sculpts don't always live up to the expectations of the BT community and the quality of the production itself can vary due to the handmade nature. They are further hampered by three factors: deadlines, lineart, and the production method.

Lineart: Catalyst only uses a single rendering of a 'Mech design (often the frontal 3/4" view) in their TROs, leaving IWM artists to interpret the rest of the details (which resulted in a trend of 'Mechs with very simplistic back sides). These images also don't always give the artist a good sense of depth, so some 'Mechs end up having different proportions than intended. Take the recent Omen, from TRO3085:

Looks like it walked right out of MWO (because it's one of Alex's designs!). Here's the mini:

Wow! What a difference. The torso and its armaments are totally out of proportion (and sits too high), and the pilotpit is just plain wrong.

Clearly the level of detail was compromised, which can be worked around by filing the cockpit down. But why is the torso so compacted? It may be a result of the mastering process, where the original sculpt is recast, leading to shrinkage (and this happens with virtually all casting processes). The parts then shrink again when cast in metal (and again, it would happen with resin too). This is another trend with IWM sculpts - their torsos tend to shrink more than the rest of the limbs (or vice versa). You can only predict shrinkage so far, so sculpting things inversely out-of-proportion doesn't always help. And sculpting things takes time - if you have to redo a part because it ended up too big or small, it could cost you weeks of time and sales.

Could IWM benefit from ever-more-affordable rapid prototyping? Sculpt-wise of course, but they still have to pay artists to completely render 'Mechs, order the prototypes, and clean them up, which may take more time than starting from scratch and Green Stuff, not to mention costs money. Their molds would likely still be made and cast by hand, so we'd probably still see seam lines and off-register parts (though they're usually good about sending new parts).

Haplo from LOTB is one guy pulling ready-made 3D objects from the game files, making them printable, and having them rapid-prototyped (just like Sentinel373), taking the additional step to clean up the resulting sculpts, and sending them off to a caster, and reselling his casts. He is likely not making a lot of money off of this (whereas TheTeacher explicitly is, though it goes toward keeping himself healthy). IWM needs to break even to survive, and to get there sometimes quality has to be sacrificed in order to get product out the door. For Haplo, this is a hobby and he can afford to take his time to get the best product possible. For IWM, this is their lifeblood.

I think if we could infuse IWM with million dollars, we would see a great increase in quality as they are able to keep up with their backlog and pay artists to get the best sculpt they can in a reasonable timeframe, though that would be a band-aid fix.

Catalyst does have plastic minis available in the Introductory Box Sets. The first run of the Original 24 (non-Unseen) wasn't great - they looked like recasts of the IWM minis, done in cheap resin which, again, shrank and mucked up the proportions. However, the 25th Anniversary set included very high-quality versions of the Loki and Thor, possibly rapid-prototyped and recast (or modified from the superb IWM sculpts). The 30th Anniversary set is promised to have superior versions of the Original 24, plus a very nice Mad Cat and BattleMaster that we have seen pictures of:

#3

Posted 30 May 2013 - 06:48 PM

#4

Posted 30 May 2013 - 07:45 PM

(I don't know if IWM actually plan to do any future minis using 3D modelling; but it would be neat if, say, some of the new 3145-era material was done using that system, as and when the time comes for some of them to be developed.)

Edited by Nerroth, 30 May 2013 - 07:45 PM.

#5

Posted 30 May 2013 - 07:57 PM

#6

Posted 31 May 2013 - 03:59 AM

#7

Posted 03 June 2013 - 02:21 AM

You have to remember one thing though, the way the custom guy is making the minis? That pretty much is the future. Most of the IWM designs were made long before 3D printing, and were merely recreated hand sculptures. That's why the 3D ones look so much sturdier & better.

Eventually they'll use those for the molds, and thus, most minis will be made on a computer from here out I think.

#8

Posted 06 June 2013 - 04:41 AM

#9

Posted 07 June 2013 - 12:18 AM

GregHM, on 06 June 2013 - 04:41 AM, said:

GregHM, on 06 June 2013 - 04:41 AM, said:

i can repeat that for Ral Partha Europe, for anyone who is interested in buying miniatures in europe

very kind and i'm satisfied with the quality

i keep praying every day that there still might be a solution for PGI to coop with Topps and release remodelled versions of the miniatures...MWO special edition or something...

#10

Posted 07 June 2013 - 03:50 AM

Iacov, on 07 June 2013 - 12:18 AM, said:

Iacov, on 07 June 2013 - 12:18 AM, said:

Everyone does...

If only Weisman knew his thing back when he was deciding which ways to sell the IP: http://www.gamasutra...php?story=24673

#11

Posted 07 June 2013 - 06:56 AM

#13

Posted 07 June 2013 - 07:52 AM

Adridos, on 07 June 2013 - 07:23 AM, said:

Adridos, on 07 June 2013 - 07:23 AM, said:

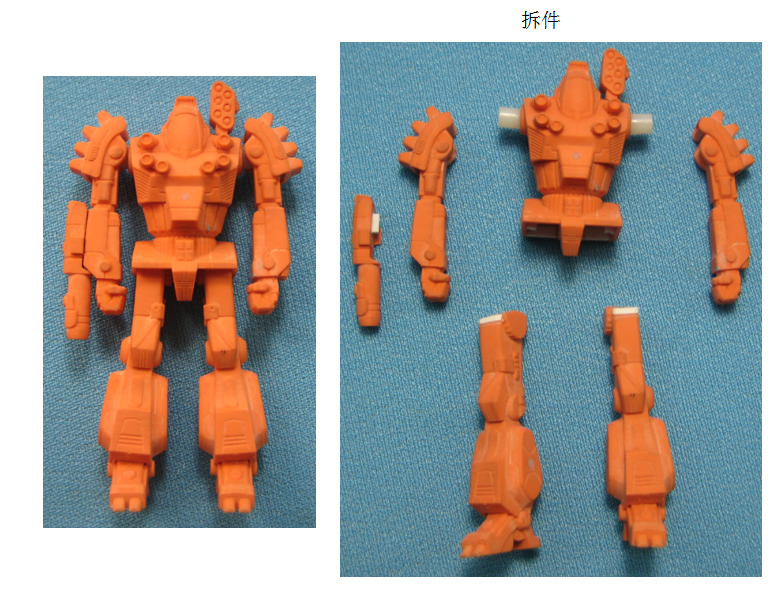

I mean, really, compare this:

To this:

*sigh* You're right I guess, I just don't want to see IWM go under. Hopefully they'll wise up and start using more modern methods and sculpts, or stuff like you've just linked will quickly outstrip them.

#14

Posted 20 June 2013 - 08:31 PM

i just bought 5 mechs.....almost $80......pretty damn expensive for some of the sculpts being from the early 90s.

#15

Posted 21 June 2013 - 11:52 PM

#16

Posted 22 June 2013 - 12:24 PM

#17

Posted 22 June 2013 - 05:39 PM

SteelWarrior, on 20 June 2013 - 08:31 PM, said:

SteelWarrior, on 20 June 2013 - 08:31 PM, said:

They can't afford it. First is the initial cost of switching to plastic injection (which is what you'd need to do for volume and ease of production - if you're just going to pour slow-cure resin into rubber molds, there's no point in switching from pewter) which would be in the tens of thousands of dollars. Then the issue of molds - for your typical Hasbro action figure, the steel dies for plastic injection can also run into the tens of thousands of dollars depending on complexity for one figure (and it's not worth doing a single 'Mech per mold - need to have multiples to make the cost worth it). Finally, the issue of sales - BattleTech is not a huge game, and you are not required to have BattleTech miniatures to actually play in the majority of cases. In order to justify the cost of switching to plastic injection, IWM would have to be able to guarantee that they can sell enough 'Mechs of a certain mold to cover the cost of that mold. For every 'Mech they plan to offer. This means that we would see tons of the popular designs (Mad Cat), but more obscure/ugly designs (basically anything currently in the IWM archive, like the Supernova) might never see production at all.

I work in jewelry - the cost of making a single master, making a rubber mold of it, and lost-wax casting it is much lower (a few hundred dollars' in materials) compared to what goes into even one injection-molded plastic piece.

Edited by ValdnadHartagga, 22 June 2013 - 05:40 PM.

#18

Posted 23 June 2013 - 04:34 PM

ValdnadHartagga, on 22 June 2013 - 05:39 PM, said:

ValdnadHartagga, on 22 June 2013 - 05:39 PM, said:

They can't afford it. First is the initial cost of switching to plastic injection (which is what you'd need to do for volume and ease of production - if you're just going to pour slow-cure resin into rubber molds, there's no point in switching from pewter) which would be in the tens of thousands of dollars. Then the issue of molds - for your typical Hasbro action figure, the steel dies for plastic injection can also run into the tens of thousands of dollars depending on complexity for one figure (and it's not worth doing a single 'Mech per mold - need to have multiples to make the cost worth it). Finally, the issue of sales - BattleTech is not a huge game, and you are not required to have BattleTech miniatures to actually play in the majority of cases. In order to justify the cost of switching to plastic injection, IWM would have to be able to guarantee that they can sell enough 'Mechs of a certain mold to cover the cost of that mold. For every 'Mech they plan to offer. This means that we would see tons of the popular designs (Mad Cat), but more obscure/ugly designs (basically anything currently in the IWM archive, like the Supernova) might never see production at all.

I work in jewelry - the cost of making a single master, making a rubber mold of it, and lost-wax casting it is much lower (a few hundred dollars' in materials) compared to what goes into even one injection-molded plastic piece.

See and this is where I want to call ********. I find it interesting that IWM whos been producing metal miniatures out of the same few hundred master molds (already long time payed off in the 90s) cannot afford to make the switch to plastic, meanwhile Catalyst games can afford to pay a company to produce their intro box with 26 miniatures in it, 2 times over, and still sell it along with game boards and rule books for less than $60. Granted its a horrible quality plastic, however they still obviously had to create the master mold that would be of a high quality (the warping/deformation is from the harder "toy" plastics used, not in the actual mold, which is why you see such a variance between box sets).

Now I understand IWM may not be able to front the cash to make the switch themselves, which is why i think Kickstarter is the right course for them. They raised enough money ($30 000) to make 9 WoB LAMs, which IMO is a product aimed at a very small % of Battletech players. Theres many who hate Comstar/WoB, many who never play with LAMs to begin with, and alot of players who wont touch anything post 3069. You cant tell me that a kickstarter aimed towards $100 000, with a pledge level of $100 getting you 25 of the highest quality, most popular plastic battlemechs wouldn't get funded. Currently we pay on average $12.50 per mini in the format of metal. The Robotech kickstarter that just got funded for 1.4m was offering miniatures for less than $5 each, same scale, higher detail, and using a 3rd party to produce, AND paying royalties on top of it.

As for Battletechs popularity, is it played today at the same % as Warhammer? No. However it has been around for 25 years and is one of the most recognized tabletop games out there, many who do not actively play at the moment are familiar with what it is, and often buy into things like the intro box set. The popularity of the game is stunted by the fact that the game pieces are 30 years old and lacking any customization. Its not a matter of battletech being a small cliche group, its a matter of the companies who product the gaming materials not willing to make the changes necessary to boost their bushiness. Look at Warhammer, they make thousands off of people who dont even play the game, people who just like to paint their minis and enjoy the hobby in itself. IMO Catalyst Games is the best thing to happen to Battletech in the last dozen years, their fresh approach to new concepts and their willingness to grow their franchise is meeting success. My local battletech facebook group has doubled its members in the last few months, and more and more people are coming back to the game.

At the end of the day ask anyone whos familiar with the miniatures produced for Battletech. They will say the majority of them are horrible. And seeing as this is a TABLETOP MINIATURES game, that's half the battle right there.

Edited by SteelWarrior, 23 June 2013 - 04:38 PM.

#19

Posted 27 June 2013 - 10:37 AM

I agree that if we could kickstart IWM into upgrading to injection plastic, things can only get better. The remaining concern is their phsyical space - they just have enough space for what they do (see: http://www.purplepaw...ech-miniatures/). A contemporary plastic injection machine is about the size of two desks end to end. IWM would probably want to have more than one of those machines, so that they have a backup in case one fails. That's an entire room just for those two machines. That probably means they have to clear out their old equipment, which not only takes time and effort, but leads to another point: licensing.

IWM is specifically licensed to produce pewter (and occasionally resin) miniatures for various properties. Were they to switch over exclusively to injection plastic, each one of those licenses would have to be revisited and renewed, which can be an expensive legal process. Granted most of those are Catalyst properties, but if an IP holder does not want the product to be manufactured in plastic, IWM is in a sticky spot because they wouldn't have a space to safely continue doing both processes. They could even end up losing a license if they switched completely over to injection and a licensor was insistent on pewter product only. Unless they also got a bigger space to work with.

Furthermore, since the injection machines would take quite a while to pay for themselves, IWM's sales models might change - we might see more lance packs, bulk packs, et cetera in order to keep product moving (OR a scenario much like Games Workshop, where the price for a pewter mini is the same as the price for the plastic version). If IWM underproduces, they lose money on operating costs. If IWM overproduces, they lose money on back stock. That in turn affects the game itself - if players are ending up with far more miniatures than they would like to use in a game (which already takes forever to play with just a lance), it might be in CGL's best interest to accommodate that (which we see manifesting itself as BattleForce/Quick-Strike/Alpha Strike).

To get IWM to a point where it can sustainably produce injection plastic, they would basically have to upsize the entire company. More space, extra hands (especially at least one technician to operate and maintain the injection machines), new licensing agreements. That would take much more time, effort, and money than Kickstarting just a single machine.

Finally: BattleTech has never been a miniatures game. The classic BattleTech has always been a board game, playable with anything from cardboard standees to pennies with arrows drawn on them. There is no requirement to use miniatures; in the truest spirit of the game, miniatures are superfluous (though that's no excuse for low production value).

#20

Posted 27 June 2013 - 12:25 PM

One case in point is what happened with Mongoose and ADB, and their efforts with the Starline 2500 miniature line. Initially, the idea was for the entire line (all of which are done using 3D models) to be cast in resin... but after numerous teething problems, that turned out to be far too ambitious a task. Eventually, both sides agreed to shift the bulk of the 2500 series to metal, with only a handful of the largest ships (such as the Klingon C8 or Romulan Condor) still done in resin.

And it seems that the actual quality of the metal 2500s is higher across the board, at least in terms of QC issues.

So, in principle, IWM could stick with metal and still go with 3D modelling, if that was the best way forward for them.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users