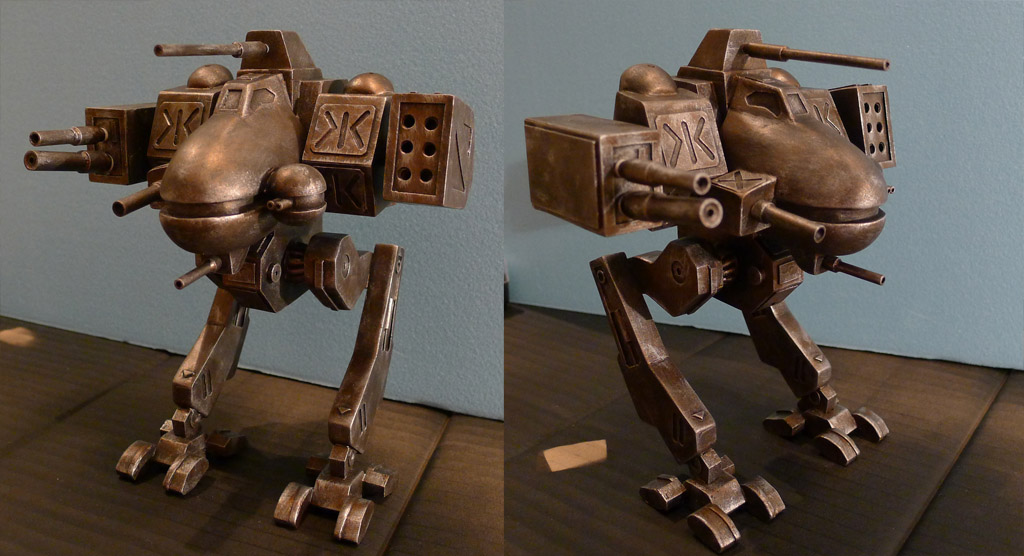

I then gave it a nose job

This model was to be my first go at pressure casting resin which to cut a long story short means far superior copies.

Building the home made vaccum/pressure chamber was a MASSIVE pita! A heady mix of dyslexia, imperial and metric parts meant I ordered lots of wrong size fittings much to my frustration. Added to that I was told to fill the master with resin this was a major mistake the resin and the styrene reacted with each other and the masters went goopy in places "oh noes *cries*"

The model almost got binned but I got talked into fixing it and I'm glad I did. All the parts have been moulded and pressure cast in resin.

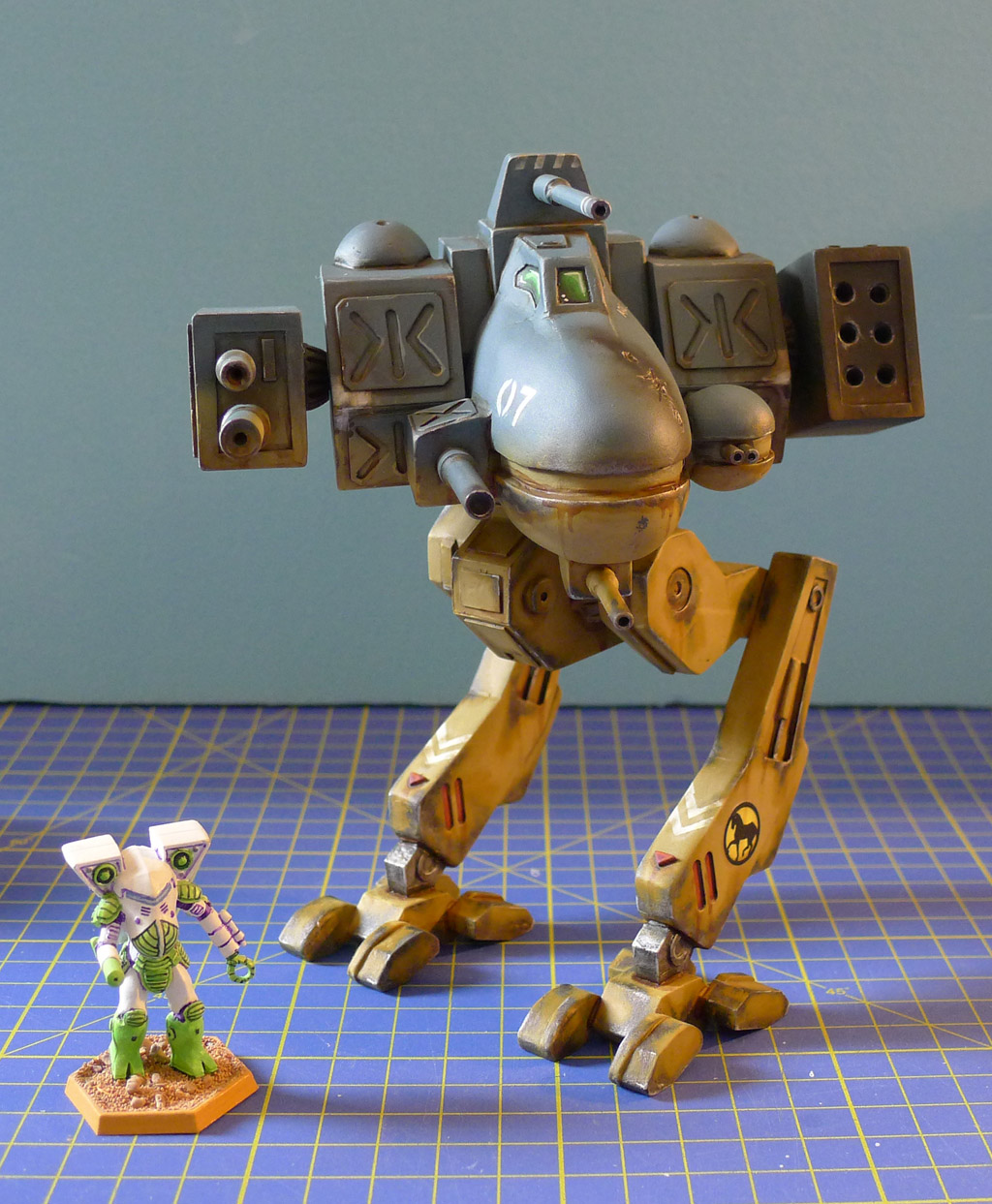

It's standing here primed (black, tin, boltgun metal) ready for the first coat paint. While the legs are assembled the upper body is not glued to make for easier painting.

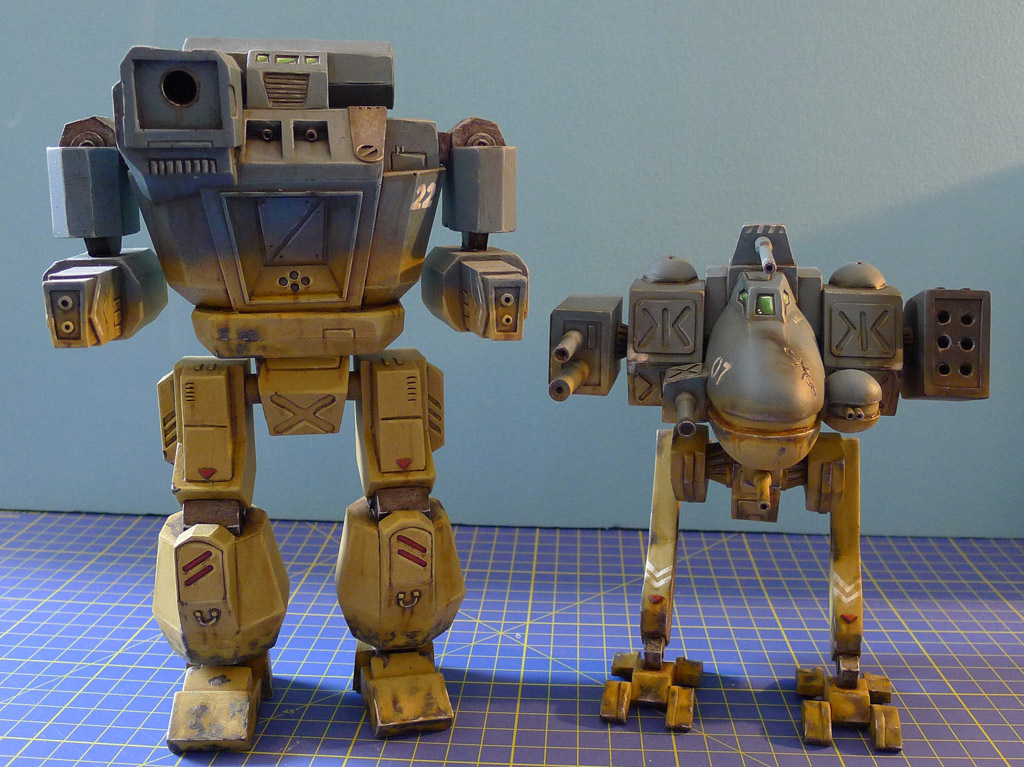

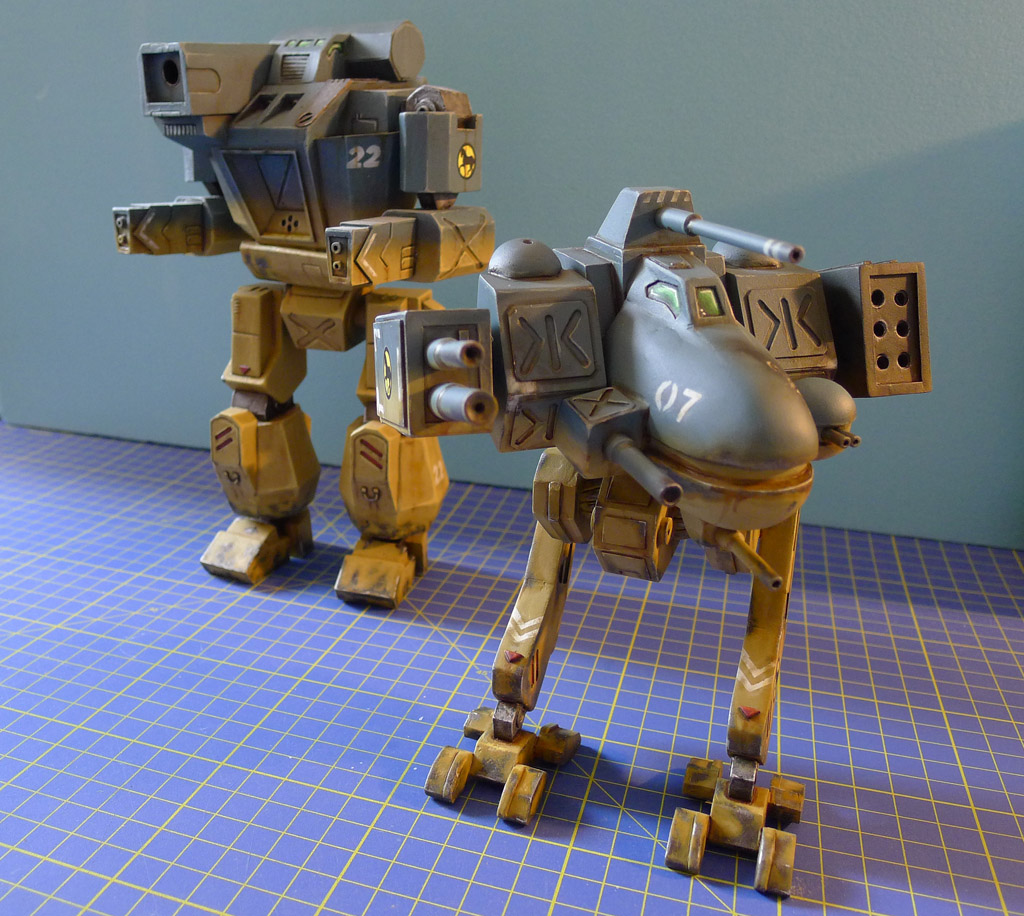

So here's the finished model. She stands in at 16cm in ELH two tone desert ridge line, nice and battle worn, an AC10 shell has brushed CT but she's still good to go.

Edited by lyonn, 12 March 2012 - 10:18 AM.